3D Design Power

Industrial Design System

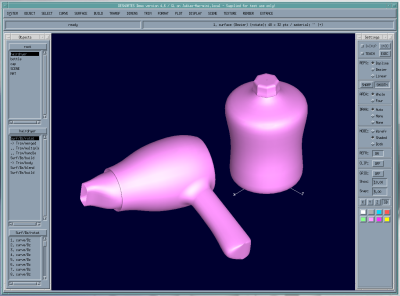

DeskArtes Industrial Design System

IDS is a software package which has been specially developed as a design tool for industrial designers. In the most user-friendly way, DeskArtes performs all the tasks required for designing and styling of industrial products.

DeskArtes IDS has found acceptance across a large range of industrial design environments, from large manufacturing companies through to small independent design houses. Many images contained on these and the other product description pages are 3D computer models rendered with DeskArtes IDS. For further examples, see the DeskArtes Image Gallery.

DeskArtes IDS is supported on Windows XP and Mac OS X platforms. Older versions also available for SGI IRIX.

For an overview of the functionality of DeskArtes IDS, check the Product Description. To further understand how your company could benefit from the software package, see the Key Benefits.

How are these benefits achieved? Let us review the features of DeskArtes design software for the answer:

Importing Design Constraints

The design can be subject to a number physical constraints. These can be the design geometries of components and sub-assemblies which are part of the product. If these have been engineered using a CAD system, they can be directly imported into DeskArtes format. Engineering modifications can be quickly imported greatly reducing cycle times. Alternatively, the parts can be modeled quickly in DeskArtes software. Hence the designer produces only designs which are consistent to these physical constraints. So the number of prototypes and design iterations is greatly reduced, which saves a great deal of time and money.

Conceptual Design

DeskArtes provides the user with an environment which is intuitive and unobtrusive which fosters innovation and creativity. The designer can quickly investigate many different ideas and approaches, taking advantage of DeskArtes' real-time inter-activity and high degree of realism. Many more designs alternatives can be generated as the need for conventional prototypes is considerably reduced. Therefore quality improves.

Product Validation and Manufacturing

Designs can be exported from DeskArtes software to CAD/CAM systems for validation by engineering and manufacturing. This greatly reduces design cycle times and lead times to manufacturing.

Direct Link to Rapid Prototyping

The substantial cost and time spent producing conventional prototypes can be greatly reduced as virtual prototypes can be used. If physical prototypes are required then they can be produced quickly using rapid prototyping machines. DeskArtes can generate error free STL files which other surface modelers cannot. This saves time and money.

Collaboration with Marketing

The opportunity for collaboration between the designers and the marketers is greatly enhanced as DeskArtes provides an interactive communication channel for the discussion and development of ideas. Many different product design alternatives can be explored concurrently and the final choices can be made much closer to the introduction of the product to the market. This all leads to a better product design choice being made.

Customer Involvement

DeskArtes provides the opportunity for more significant involvement by the customer in the product design process. Customer feedback can be obtained for new products represented by virtual prototypes. Some DeskArtes users skip prototyping and pre-production completely. The photo-realistic images produced by DeskArtes software are included in their product catalogues and manufacturing proceeds only against orders.

Integration

DeskArtes' data integration capability not only leverages investments in CAD/CAM systems but also creates an integrated solution which provides the means by which different functional groups form a multi-disciplinary team to tackle the challenges of new product development. This yields significant reductions in "time to market".

The "time to market" for new products is a critical factor. The success or failure of the product can be determined by this. Reductions of over 50 % are typically achieved in an integrated CAD/CAM or rapid prototyping environment using DeskArtes software.